Metal Coating Patent Co-Op

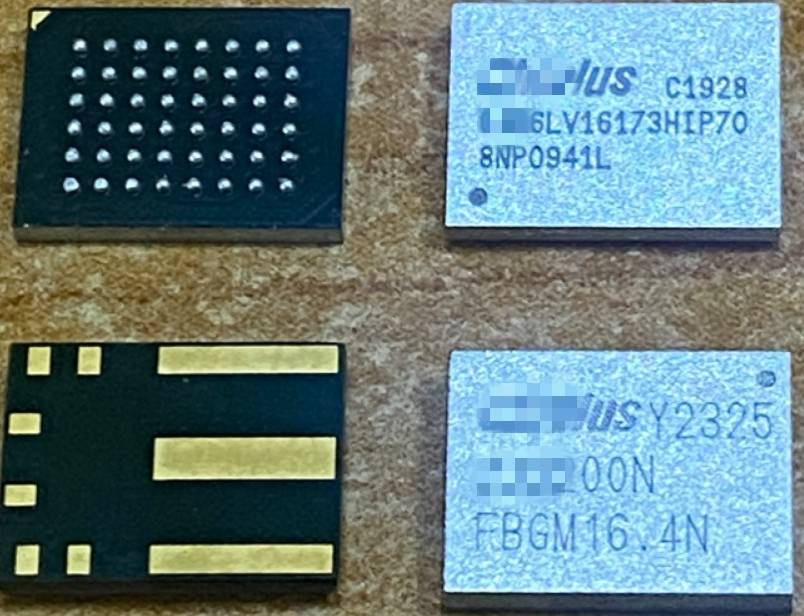

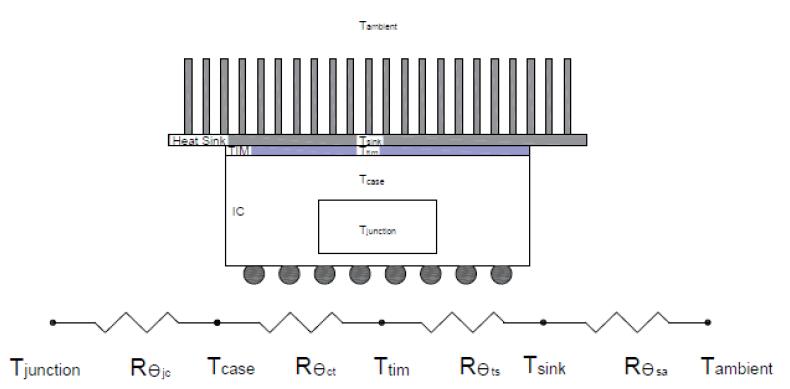

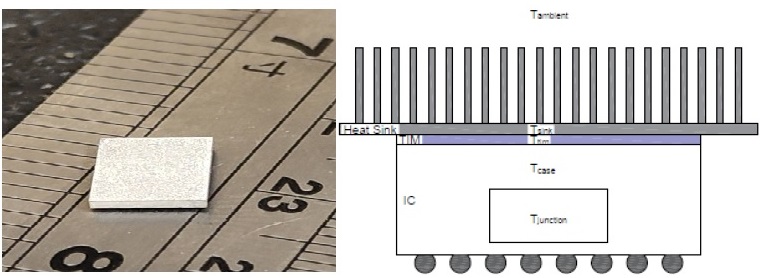

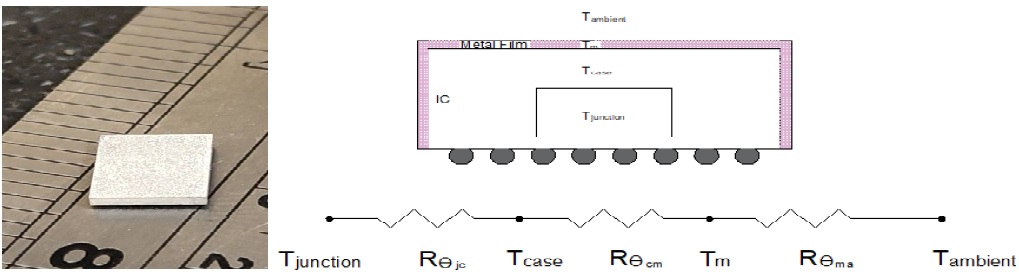

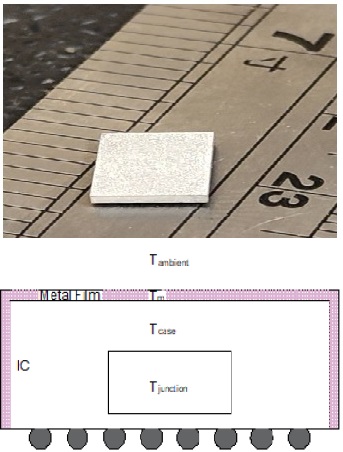

Efficient computing is accompanied by the junction temp temperature generated by high-frequency power supply\memory memory overclocking processing applications, and the gas\liquid cooling system in the BAREBONE barebonese system, but how to conduct the heat generated by the chip to the IC surface through the EPOXY to accelerate convection and radiation with the active cooling system more effectively, improve the efficiency and extend the life; At this stage, the same SOLUTION PROVIDER uses 5~8um nickel film to achieve this purpose by sticking 5~8um nickel film on the surface, however, the heat dissipation coefficient of nickel is low, the adhesive medium reduces heat conduction, and the production efficiency is low and the cost is high; Our patentedmetal film thickness is only 0.2um, using the heat dissipation material for better heat dissipation coefficient and cheaper metal aluminum, supplemented by production technology can be used in IC packaging (IN-LINE PROESS) or post-package (POST-PROCESS) to process heat dissipation coating, flexible process, high efficiency, and very low cost.